CADWELD® PLUS connections offer all the benefits of conventional CADWELD® connections:

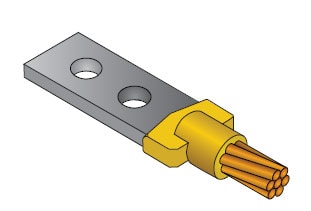

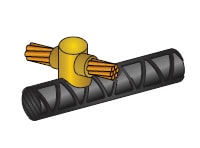

Current carrying capacity equal to or greater than that of the conductor

- Withstand repeated fault currents without failing during operation

- Permanent, molecular bond that will not loosen or corrode, resulting in a connection with a lifetime equal to that of the installation

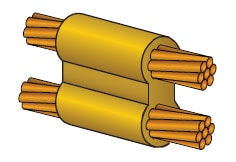

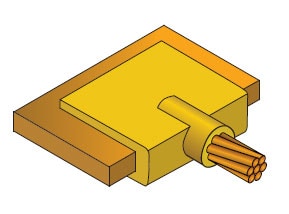

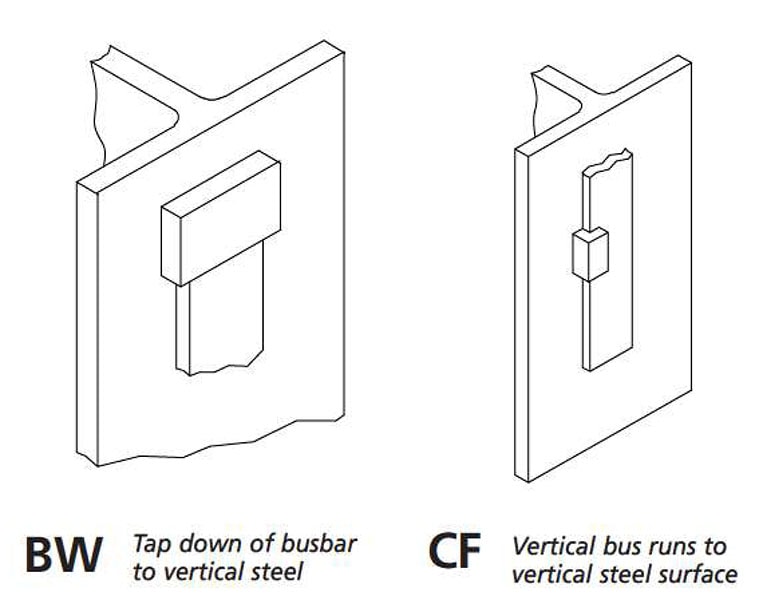

- Join copper to copper, copper to galvanized or plain steel, copper to copper clad steel, copper to bronze/ brass/stainless steel, steel to steel, etc.

- No external power or heat source required

- Quality Assurance Inspection is easy and visual

- Minimal installation training required

- Exceed requirements of “IEEE® Std 837- Std. for Qualifying Permanent Connections Used In Substation Grounding”

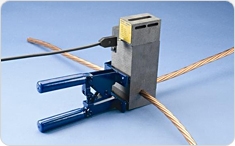

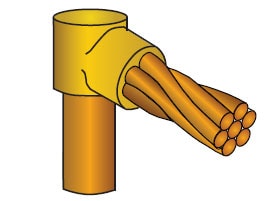

The CADWELD® process is a method of making electrical connections of copper-to-copper or copper-to-steel in which no outside source of heat or power is required. In this process, conductors are prepared, placed in a purpose-designed graphite mold, and exothermically welded to produce a permanent electrical connection.

The CADWELD exothermic process is a system. Materials from other manufacturers should not be mixed or matched with CADWELD molds or welding material.